226-232 Highland Street, Roxbury, Boston, MA 02138

Parcel Area: 9,612 SF

Total Project Size: 7,883 SF

SITE DESCRIPTION

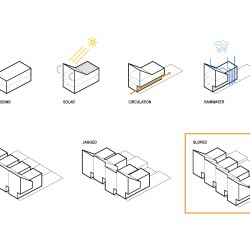

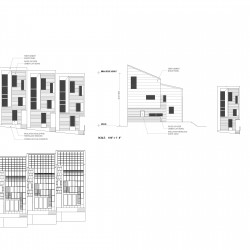

Site Conditions – Fronting on Marcella Ave., Highland St., and Fulda St., the site gradually slopes up from Marcella Ave. to Fulda St. The site is vacant however records from 1899 show a multiple residential buildings tight fitted on the site.

Adjacent Uses – Residential uses with one, two, three, and multi-family wood frame buildings surround the site. Across Marcella St. is the Connolly Playground, a tree edged neighborhood park with sport fields, courts, play structures and passive use areas.

Zoning – 3F-4000 / 2F-5000, as shown on Map 6D of the Boston Zoning Maps in the Roxbury Crossing District.

PROJECT TEAM

Developer/Design Manager: Urbanica, Inc

Architect of Record: Urbanica Design

Design Architect: Interface Studio Architects

LEED Consultant: Interface Studio Architects

Energy Consultant: Conservation Services Group

Green Rate/LEED for Homes Provider: Conservation Services Group

Mechanical Engineer: Engineering Design Build

DEVELOPMENT CONCEPT

Vision Statement

A POSITIVE smaller footprint

Create a low-cost, energy-positive, and environmentally sustainable multi-family housing that stands as a model of responsible, contextual residential development.

Based in a holistic approach toward sustainability, using both low and high technologies in creative, efficient ways at all levels. However, it is the belief of the team that sustainability is not simply a technological fix, but a reconceptualizing of our outlook on the relationship between ourselves, the environment, and our lifestyle. The goal thus was to promote housing that actively engages residents with their local environment, neighborhood, city, and region. By re-evaluating and investing in our existing neighborhoods, they may become denser, more diverse, and more active while maintaining a smaller footprint on the earth.

General Description

An adaptable townhome unit that is a replicable prototype of efficient residential construction for Roxbury. The building consists of four typical three-bedroom units, approximately (1970 SF) each, in a row house configuration.

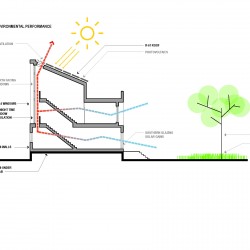

The building’s form and orientation serve to maximize natural daylight and solar gain for the photo-voltaic arrays generating, over the course of the year, more electricity than is needed on site. The approach includes two major strategies for energy reduction: first, a super insulated envelope minimizes heat transfer without relying on mechanical conditioning techniques; second, feedback mechanisms that provide information and prompt to users in the house regarding their energy-related activities. The project is thus efficient in energy, resources, use, and space throughout.

Passive Features

- Passive Solar

The southern façade is glazed to take advantage of solar heat gain in the winter. Deep overhangs and window depths reduce heat gain in the summer months.

- Daylighting

Daylighting is maximized to reduce reliance on artificial lighting.

- Super-Insulated and Airtight Building Envelope

Ceiling/Roof: 14’’ TJI with dense-packed cellulose + R-15 rigid above (R-62)

Wall construction: 12” double 2×4 dense-packed cellulose with Zip system sheathing and Siga taping (R-40)

Windows: Schuco Brand, Low-E, triple paned uPVC windows are utilized. U-value 0.139

Floor Over Basement: 14’’ TJI with dense-packed cellulose + R-15 rigid below (R-62)

- Passive Ventilation

Air flow is allowed to move from the lower floors of the home to the top floor. Upper level windows and a clerestory condition allow for venting excess heat and help to provide more consistent interior temperatures.

- Site Water Management:

Rainwater harvesting done through rain barrels at downspouts and the collected water is used to supplement on-site landscape irrigation.

Rain gardens with drought-resistant native plantings are incorporated.

Turf is minimized and a Drought Tolerant Fescue ground cover is selected to reduce required irrigation.

Active Features

- Mini-Split Units (Energy Star)

o Mitsubishi H2i Hyperheat MSZ FE09NA/MUZ-FE09NA, 26 SEER, 10 HSPF

o Mitsubishi MSZ-GE09NA/MUZ-GE09NA, 21 SEER, 10 HSPF

- Zehnder ComfoAir 350 Heat Recovery Ventilator at (Effective Heat Recovery over 75%).

- Blower Door Test: Infiltration was test at be 0.57 ACH (air change per hour) at 50 Pascals pressure difference.

- Rheem SolPak RS80-40BP, 40 square foot solar thermal panel (2.4 Solar Energy Factor) with an 80 gallon storage tank for hot water requirement.

- Efficient shower heads (1.5 gpm), faucets (1.5 gpm) and fixtures are used throughout.

- 235 W Panasonic HIT PV panels (Model VBHN235SE01) with an module efficiency of 18.6% (Installed at 4:12 slope)

- Enphase Micro Inverters (95.5% Efficiency Rate) Model: M210-84-208-Sxx

- CFL Recessed Lighting and Fixtures

- Appliances

Bosch 300 Series Appliances

Electric Cooktop and Oven

Refrigerator – Energy Star

Dishwasher – Energy Star

Washer/Dryer not provided

PROJECT TIMELINE

Zoning Approval May 2012

Building Permit Approval September 2012

Closing/Construction Start September 2012

Construction Complete September 2013

Sales/Closing September 2013 (226 Highland)

October 2013 (230 Highland, 232 Highland)

November 2013 (228 Highland)

COMPETITION SUBMISSION

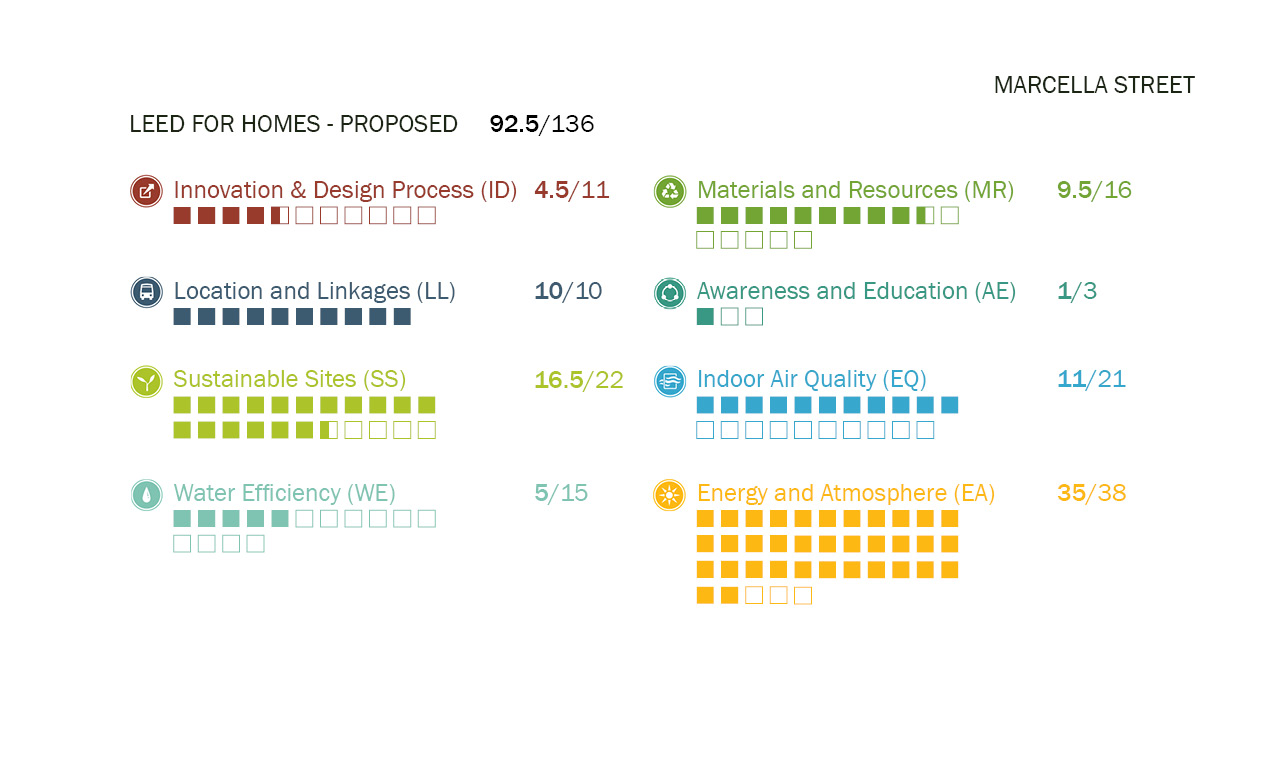

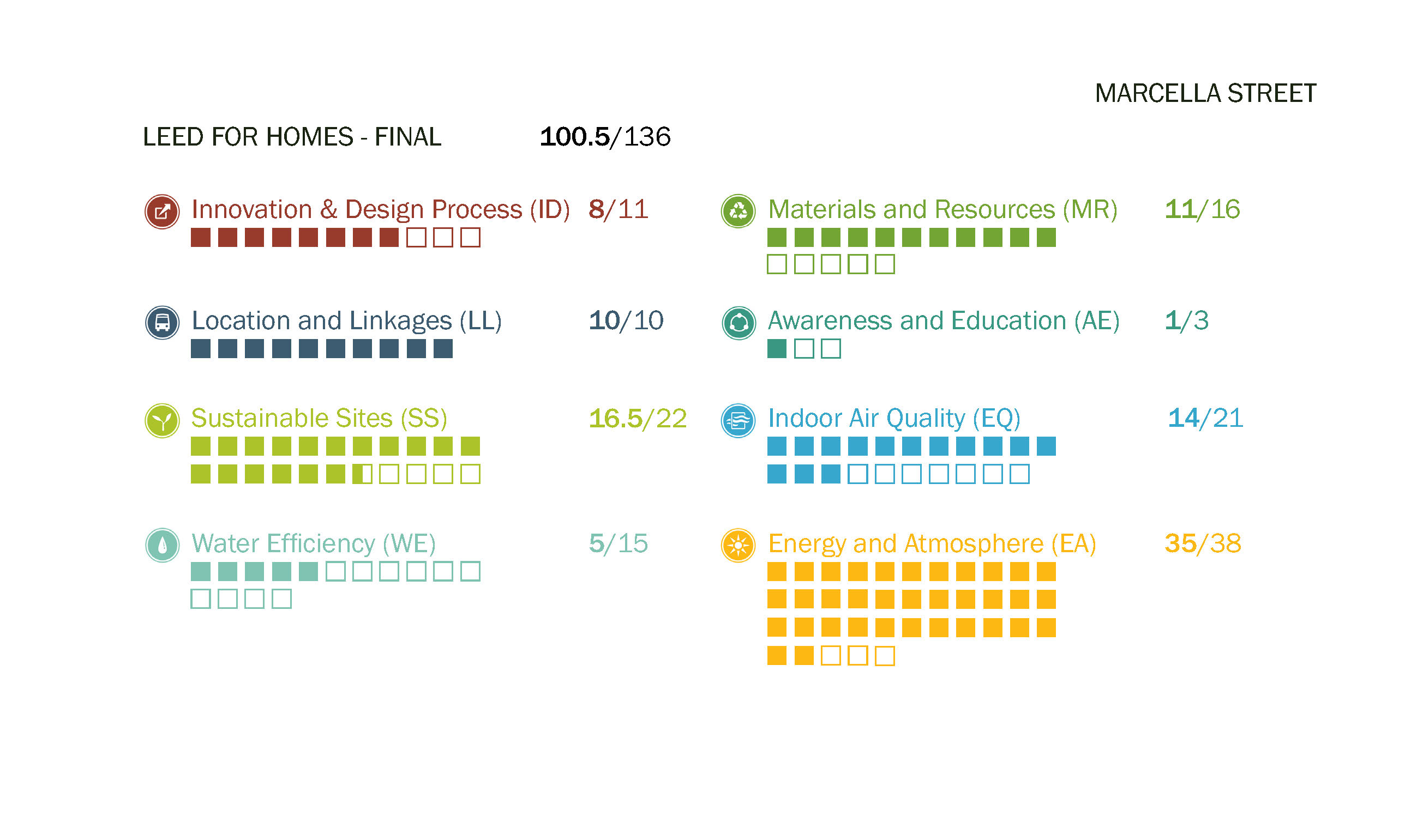

BUILDING PERFORMANCE AND LEED CHECKLIST

Click on each image for a detailed LEED checklist.

HOME ENERGY RATING CERTIFICATE

OCCUPANT OBSERVATIONS

Driven by rising energy costs and a desire to adopt a more sustainable lifestyle, Ted, his wife Suleyken and their two kids were looking to upgrade to a contemporary, energy-efficient house in a transitioning neighborhood. Their online search for housing led them to Boston’s E+ green building program and after a site visit in April 2013, they were quick to place a bid on the house and move in by end of the year.

They have been living in the house for over six months now and their level of thermal comfort satisfaction is beyond what they had previously expected. They believe that the design of the house itself encourages them to live more sustainably. With the need to cool or heat the house drastically reduced because of the integrated design features of natural ventilation, daylighting, optimal thermal insulation and heat recovery system, they are continually saving on the energy costs and in the process reducing their carbon footprint!

Furthermore, the solar panels on the roof produce more electricity than the house consumes, making it an ideal case for an energy positive or E+ house. The excess electricity hence produced is fed back to the grid, the owners enjoy rebates making solar panels a financially viable and technically feasible option.

Comparable to a conventional house in operational maintenance and capital costs, this E+ house presents a sustainable model of development that is quick to grasp and easy to hold on to. Ted loves to experiment with the settings of the Embue thermostat and the solar panel Powerdash, even the window opening for natural ventilation to further optimize their energy usage. The more he learns, the more he makes the house save for him. It is not surprising that the E+ program is leading by example and encouraging similar growth in the neighborhood and throughout the city.

BEST PRACTICES AND LESSONS LEARNT

-

-

-

-

-

-

-

-

- Make key decisions early in the design process to lessen design revisions and construction change orders

- Have an Integrated Project Team with both broad skillsets and specific/specialized skillsets to provide a holistic approach to design and construction

- Identify big cost items and evaluate the Cost-Benefit Analysis for the short time initial cost vs. lifetime cost

- Educational and informational sessions for local residents, industry professionals, contractors/suppliers to promote green/sustainable design and construction

- A site conscious building massing design and good solar orientation is crucial to maximize on Solar PV production

- Balance the cost implication and energy goals to produce a feasible project

- Select subcontractors and suppliers with working knowledge of Green/Sustainable practices and with an absolute desire to learn and innovate

-

-

-

-

-

-

-

- Photo by Sam Oberter

- Photo by Sam Oberter

- Photo by Sam Oberter

- Photo by Sam Oberter

- Photo by Sam Oberter

- Photo by Urbanica

- Photo by Urbanica

- Photo by Urbanica

- Photo by Urbanica

- Photo by Urbanica

- Formwork for Footings, recycled steel for rebars

- Backfilling of crawlspace

- Process of filling the concrete rat slab, underlayment of vapor barrier

- Sillplates, with certified lumber from Sterrit Lumber

- Installation of floor joists, using engineered lumber (TJI and LVLs) for accuracy and less waste

- Union crew carefully installing floor joists and rimboards

- First floor walls up, ZIP system sheathing as water resistive barrier

- First floor walls up, ZIP system sheathing as water resistive barrier

- View of project nestling at the foothills of Fort Hill

- Exterior Layer of double wall being erected

- Idea to reality: Back Façade View reminiscence of initial project rendering

- Close up of the Exterior for 232 Highland Street

- Inverted Bay is taking shape

- View of Project gently staggering and stepping down the slope from Fulda St

- Looking through the forest of wall studs

- Looking through the forest of wall studs

- Exterior view of the Zip System walls

- One panel of the double walls stud (built in panels beforehand) being raised up by framing crew

- View of double studded wall in bedroom 2.

- Site manager buried in snow during Blizzard “Nemo” 2013

- Neighborhood kids having fun in the streets in the aftermath of Blizzard “Nemo.”

- View of inverted bay from staircase

- Cozy study nook with a big picture window in the inverted bay

- Tall window framing views when walking down the stairs

- Framing crew working with safety harness and protective gear

- Exceptional ceiling height for the 3rd floor bedroom

- Window openings framing views of hillside

- View of Project from upper Highland St.

- Front Façade View reminiscence of initial project rendering

- Delivery of building materials to the 3rd Floor Deck

- Installation of the floor sheathing, note the doubling up of the joists around the exterior deck location

- Wood studs for the 3rd Floor Walls

- Wall Segment is lifted by forklift during installation

- Framers raising, bracing and leveling the exterior wall segment

- Neighbor walking his dogs along the North Façade on Highland St.